Unleasing the power of Flujo GFRP

A Revolution Beyond Steel

Flujo GFRP, a revolution beyond steel highlights the emergence of Glass Fiber Reinforced Polymer (GFRP) as a potentially transformative material in various industries, promising advancements that go beyond the conventional uses of steel. With potential benefits, innovations, and paradigm shifts that GFRP could bring to the forefront. Let's delve into the explanation:

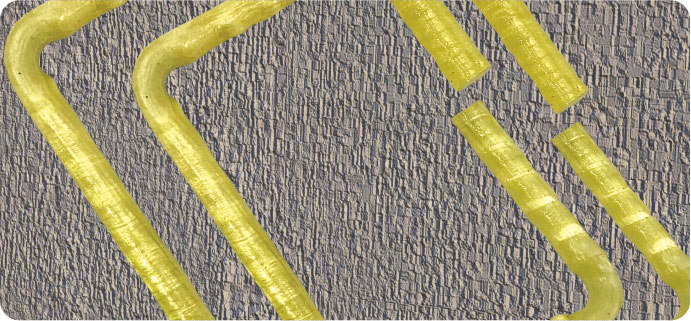

Introducing Flujo GFRP Bent Elements

Combining the strength of glass fibers with the flexibility of polymer, Flujo GFRP Bent Elements show potential in construction. With meticulous crafting, they seamlessly fit diverse architectural contexts, going beyond conventional boundaries. Adapting to intricate designs, these elements boost structural resilience and endurance while inspiring creativity.

The fusion of engineering and artistry in Flujo GFRP bent elements signals a fresh chapter in architectural innovation and construction practices.

Issues with TMT Bar

Here are some common issues faced with TMT bars:

Corrosion

TMT bars are susceptible to corrosion when exposed to moisture, chemicals, or saline environments. Corrosion can weaken the bars and lead to structural integrity issues over time.

Increasing Cost

The cost of TMT bars has been subject to fluctuations due to factors like raw material prices, transportation costs, and market demand. This volatility can impact project budgets and overall construction expenses.

Scrap Generation

During construction, TMT bars may require cutting and bending to fit specific structural requirements, leading to scrap generation. The disposal of this scrap can be a concern and add to waste management challenges.

Cutting of Opening in Concrete Structures

Incorporating openings, such as doorways or windows, in concrete structures with TMT bars can be labor-intensive and time-consuming. Special tools and techniques are often required for precise cutting, adding to construction complexity.

Labour Intensive

Handling and installing TMT bars can be labor-intensive, especially in large-scale construction projects. The bending, cutting, and placement of bars demand skilled labor and may increase construction timeframes.

TMT bar theft is a major industry issue, with losses reported up to 30%.

Vulnerable during transit due to high value and unsecured routes, these bars are also targeted at construction sites lacking proper storage and security. Most stolen bars are resold in the black market, leading to significant financial loss.

Advantages of GFRP Bent Elements

Stronger than Steel

Flujo Glass Fiber Reinforced Polymer (GFRP) is considered to be significantly stronger than conventional materials like steel in certain aspects due to its unique composition and properties.

Upto 80% Lighter than TMT Bars

Flujo GFRP rebars, mesh, and bent elements are custom-made to precise dimensions, reducing waste and minimizing rebar scraps during construction.

Upto 30% Savings as Compared to TMT Bars

Flujo GFRP rebars can offer cost savings of up to 30% when compared to traditional TMT bars, making them a cost-effective alternative.

No Theft in Transit / Site of TMT Bars

As Flujo GFRP Rebars have specific application and no resale value in the open market, they are not prone to theft of TMT bars during transit or theft at site. This will further help reduce project costs by lacs of rs.

Saving in Overlapping Cost of TMT Bars

Flujo GFRP elements do not require overlapping as traditional TMT bars do, resulting in cost savings on materials and labor.

Reduction of Rebar Scraps

Flujo GFRP rebars, mesh, and bent elements are custom-made to precise dimensions, reducing waste and minimizing rebar scraps during construction.

Rust Proof

Unlike steel bars, Flujo GFRP rebars are rust-proof, ensuring a longer lifespan and minimizing maintenance needs.

Highly Chemical Resistant

Flujo GFRP is highly resistant to chemical corrosion, making it ideal for use in aggressive environments or marine structures

20 Times the Fatigue Resistance of steel

Flujo GFRP has 20 times the fatigue resistance of steel, making GFRP more durable under cyclic loading-420, 684 cycles for GRP compare to 23,162 cycles for steel.

No Problem with Tunnel construction

Flujo GFRP’s non-conductive and corrosion-resistant properties make it well-stuited for tunnel construction, where such characteristics are crucial.

Flujo GFRP & TMT Bars

Can be used together in construction.

-

Still have questions?

Our team will answer them and help you to make the right choice